Ordering Specials from Yankee

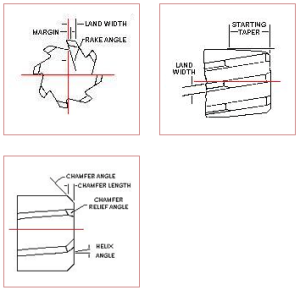

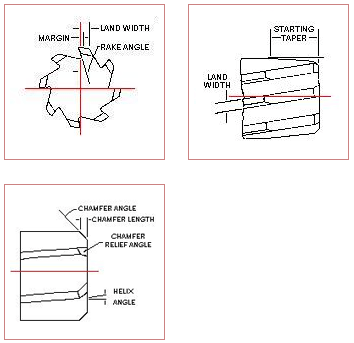

(Click here to view some definitions of terms)

In today’s machining world, there are often times when you need a specially configured reamer for your application. Unlike some manufacturers, YANKEE doesn’t scare easily. Specialty reamers have been a part of our business since inception. Therefore, we have included this page to give you, the consumer, a brief listing of the many, many options available from YANKEE (click on “options” to see them).

Alterations of Standard Tools

In the interest of saving time and money, it is always a good idea to alter a standard/stocked item whenever possible. As always, the technical staff at YANKEE is at your disposal to assist you with any questions that you may have. Features that we can provide by altering standard reamers include:

- Special Diameters on all List Numbers

- Special Tolerances on all Diameters

- Shorter Overall Lengths

- Special End Cutting Features

- Tapered Leads

- Flute Alterations:

- Non-Cutting Pilots

- Cutting Steps

- Relief Angles for Special Materials

- Tapered Flutes (these are limited by Flute Length)

- Shank Alterations:

- Drive Tangs

- 3 Flats

- Square Drives

- Morse Taper Shanks

- Keyways

- Set Screw Notches

- Oil Grooves

- Threads

- Threaded Adapters

* We also have a large selection of Over Length reamers available for quick delivery.

Complete Specials/Barstock Specials

In addition to the characteristics listed above, we can provide the following features on complete specialty items:

- Special Lengths (Overall and Flutes)

- Odd Number of Flutes

- Multi-Stepped Tools

- Different Flute Depths

- Flute Geometries for Specific Materials (Rake, Helix, Clearances, etc.)

- Left Hand Cuts

- Line Reamers (Tools with Front and Back Non-Fluted Pilots)

- Tapered Flutes

- Tight Concentricity Tolerances

- Sizes Larger than 1 1/2″

- Oil Holes

- Chip Breakers

- Oil Grooves

- Radii (on Chamfer or elsewhere)

Coatings

Black Oxide: An economical coating that adds increased lubricity, helping chip flow. Suitable for most low temperature reaming operations.

TiN: Titanium Nitride – Reduces wear and improves chip formation. TiN is a good choice when reaming carbon, alloy, and stainless steels as well as cast iron and wrought aluminum alloys.

TiCN:Titanium CarboNitride – Similar performance to TiN, but is ideal for difficult to machine materials (gummy and high abrasive). TiCN performs well in alloy steels, stainless, and where moderate cutting temperatures are generated.

TiAIN:Titanium Aluminum Nitride – The hardest of the 3 Titanium coatings. Ideal for high temperature cutting, and adds reduced wear even in heavy and interrupted cuts. TiAlN performs well in materials such as Titanium and Nickel alloys.

Unlike many coating centers, Yankee understands that reamers need a consistent coating thickness so that your reamers meet your specifications after they have been coated.

In short, please call or fax us your blueprints for fast delivery and competitive pricing. All specialty reamers are inspected 100% using calibrated measuring devices by our Quality Control Team.