Our extensive factory stock combined with our master distributor network means decreased inventory investment for our customers. Combine this with our competitive pricing and quick delivery and you have an unparalleled cutting tool leader. All Yankee reamers are manufactured by Vermont craftsmen who take pride in their dedication to reamer quality and customer satisfaction. Their skills have earned us approval at all major aerospace, automotive, and military facilities. Not only do our reamers meet or exceed all industry standards, we strive to make our reamers the best possible.

Our technical staff is always at your disposal to assist you with any questions regarding your reamer engineering and applications. The technical department will also coordinate with the sales department to get you what you need at the best available price.

Warehouse & Shipping Departments

State of the art data collection systems maintain and track inventory levels to better serve our customers. Our excellent fill rate enables us to ship many orders the same day. All orders are double-checked prior to shipping.

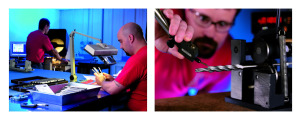

Manufacturing

Over 30 years experience, combined with specialized machinery give Yankee the edge to meet and exceed the constantly changing demands of the machining world.

Quality

Careful inspection of every reamer ensures that all reamers meet our specs.

Yankee’s quality management system ensures our tools meet or exceed the most stringent quality standards.

Yankee’s commitment to the environment

We use a computer controlled C.I. Hayes Continuous Vacuum Heat Treat Unit, which, unlike salt bath heat treating, hardens the entire reamer (not just the flutes). This process is the most consistent available and creates no hazardous waste. Having this equipment means that all heat treating is done on-site, where we can ensure that everything is done to our exacting standards.

All reamers (with welded shanks) are welded using friction welding, producing no waste whatsoever & providing a superior weld